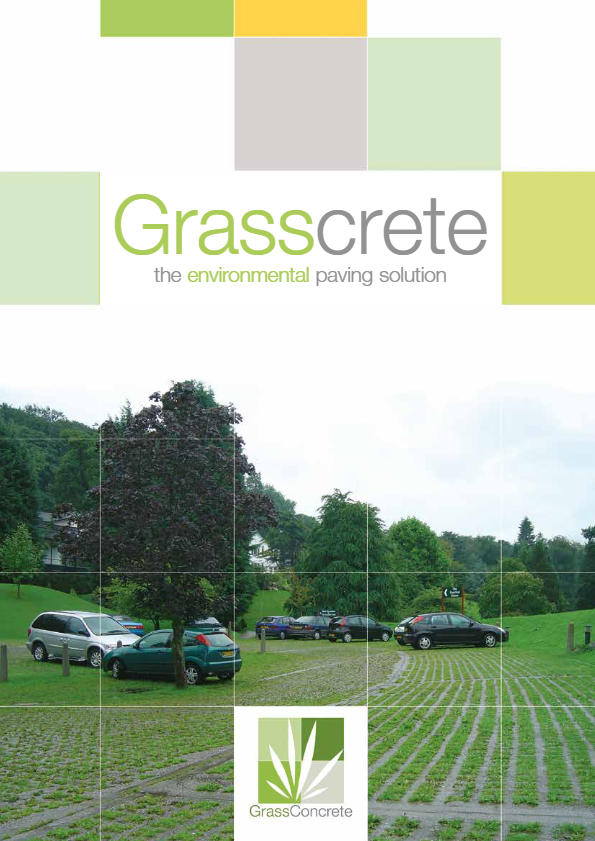

Birchwood Business Park is owned by Warrington Borough Council, and it is one of the largest business parks in the Northwest, with many nationally important companies on the site.

The park layout uses an interconnected network of paved pathways and pedestrian areas, linking communal seating areas with planting zones and water features. These are predominantly unbound ‘flexible’ block paving with reconstituted granite stone blocks, together with some highlight areas of natural sandstone slabs.

The paving was originally laid with the blocks butt-jointed in sharp sand over compacted sub-base (e.g. MOT type-1), and the narrow joints (~ 5mm), were then filled with ‘jointing sand’.

However, over longer periods of time, this paving format is not always very durable, as the jointing sand is washed out, unsightly weed growth starts from seeds that are wind-blown or from bird droppings, germinating in the joints.

After a few years at Birchwood Park, this weed growth was needing to be removed, toxic weedkiller applied, and the joints refilled with sand, at least once, twice, or more often, every year, to keep the areas looking good for tenants and their visitors, which was also becoming increasingly expensive.

Additionally, people were not happy when their access and relaxation areas became unsightly, and when restrictions were regularly being placed on their access and use. This was necessary for the disruptive, noisy and dirty works to be carried out every Spring and Summer, when use of the paved areas was obviously most popular. They were also not happy with the repeated use of toxic weedkiller and the additional restrictions and area closures this also imposed.

These increasingly frequent paving cleaning, resanding and refurbishment works were also becoming an increasingly significant annual cost for the owners and their Facilities Maintenance Contractors, J.M. & M. Scanlon from Warrington.

Therefore, back in 2017 they decided to see if they could find an alternative, less disruptive and non-toxic solution, to both prevent plant growth in the joints, and to eliminate or if possible, reduce the need for such disruptive and expensive annual works.

Several solutions were proposed and trialled to find the most effective, durable, and cost-efficient solution, including one from NCC Streetscape, the paving jointing specialists that J.M. & M. Scanlon found online through their website. NCC Streetscape’s innovation solution and recommendations, were to thoroughly clean the paved surfaces, remove any residual sand, accumulated dirt, and weed growth from the joints with high-pressure jet-washing, then to fill the joints by repointing them, not with a jointing sand of any type, but as a permanent solution with GftK vdw 850plus paving jointing mortar, applied with wet-slurry techniques.

GftK vdw 850plus is unique and the ‘state-of the-art’ in paving jointing. This is a high-performance, 2nd-generation, 2-part, epoxy resin-based, paving joint mortar, which is supplied completely prebatched, to be mixed and easily wet-slurry applied across the pre-wetted, clean paved surfaces, where it very effectively self-compacts into the joints, with no additional tooling or finishing required. After allowing 24 hours to harden, the areas can safely be reopened to the residents, no chemical weedkillers required – Job done – and permanently!

Within the first year after the trials carried out in 2017 by specialist paving contractors, CR Services, it was already very clear to everyone involved that this alternative GftK solution, was by far the best option and provided the owners and their facility managers with the ideal long-term solution. As a result, since 2018, C.R. Services have continued to work with J.M. & M. Scanlon to undertake the refurbishment and repointing of all the flexible unbound paving in this way. Today at the end of 2024, the team have completed the total of more than 8,000 m2, working in six annual phases, timed to minimise disruption and due to another advantage of GftK vdw 850plus, which is the only truly wet weather working paving jointing material, the works could also continue and be completed in cooler and wet weather, further minimising disruption to the tenants.

As a result, the Birchwood Business Park owners and their tenants are already benefitting from less disruption, and significant cost savings, as the progressively completed areas of paving have required none of the previously essential annual weed growth removal, weedkiller application, joint cleaning, resanding and waste disposal, for the past 6, 5, 4, 3 and 2 years respectively. Also, very importantly, these savings will continue to grow, as the joints in this paving will not now need any further treatment for many more years. These paved surfaces will just require normal paved surface cleaning, as and when required. Incidentally, this GftK jointing solution also makes future surface cleaning much faster and easier, as the materials are fully resistant to jet-washing, even to the use of mechanical street cleaners. The Project Leader from Scanlon recently commented: “The first phase of the GftK jointing that we installed as a trial back in 207/18, actually still looks good as new.” (815 words)